Additional Information

Collaring range: O.D. Ø12–58 mm

Punch range: Ø5–22,5 mm

Diameter of run tube: O.D. Ø16–108 mm

Max. wall thickness of tube: 3,6 mm

Tube loading length: 220-1500 mm

Pipe material: Steel, Stainless steel, Aluminium, Copper, Copper-Nickel, Copper Iron (CuFe2P)

Machine type: Industrial machines

Process: Collaring

Please contact our sales team for details regarding your needs.

Two methods, one unit, double efficiency.

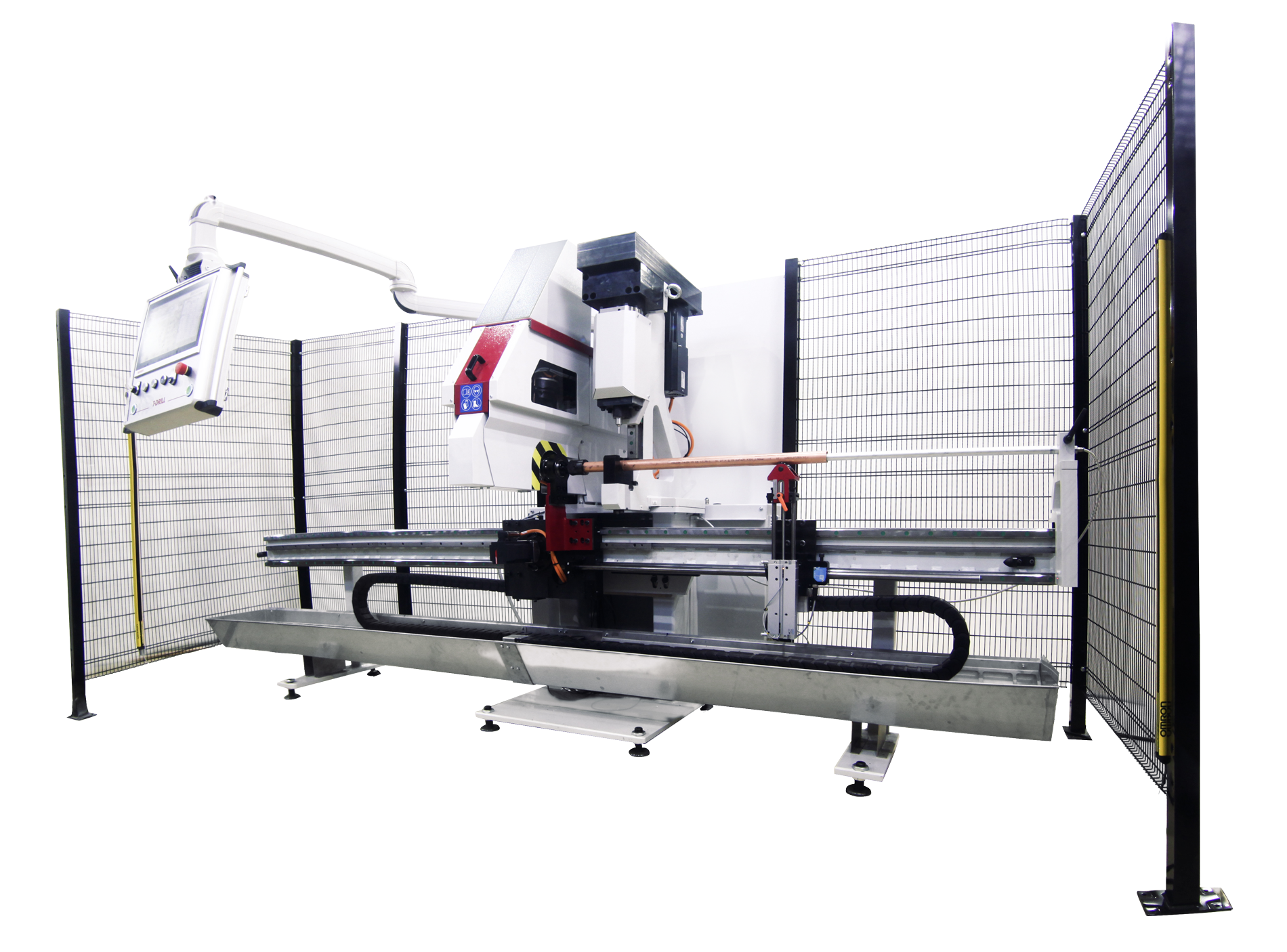

The T-DRILL S-56 PC is a cutting-edge punching and collaring unit that seamlessly combines two methods in a single unit, ensuring unparalleled efficiency and precision.

Designed for the HVACR industry, the S-56 PC offers classic T-DRILL Collaring alongside OD Punching in one cohesive system. Experience the swift production of C19400 Copper Iron (CuFe2P) manifolds with 50% less material handling, addressing the challenges in manufacturing coils for high-pressure CO2 systems.

Additional Highlights:

If you are interested in receiving a customized offer, you can find our contact information at the link below.

You can also send a pipe specification sheet through our contact form.

COMPARISON: Welded Fittings vs T-DRILL Collaring & Flanging

CUT COSTS, IMPROVE EFFICIENCY, AND SAVE A MILLION PER YEAR WITH T-DRILL METHOD.

Use the calculator to see how much you can save with T-DRILL method.

| S-56 PC | Value |

|---|---|

| Collaring range (Drilling/collaring/trimming) | O.D. Ø12–58 mm | ½"–2 ¼" |

| Collaring range (Drilling/collaring) | I.D. Ø6–54 mm | ¼"–2 1⁄8" |

| Materials for workpiece | Fe, Stainless Steel, Al, Cu, CuNi, Copper Iron (CuFe2P) |

| Diameter of run tube | O.D. Ø16–108 mm ⁵/₈”–4 ¼ |

| Compressed air supply | 6–9 bar 87–130,5 psi |

| Punch range | Ø5–22,5 mm | ¼”–7/8” |

Share on social media