Additional Information

Chamfering: 21,3–219,1 mm | .840”–8.625” OD

Expansion: Copper: 60–219,1 mm | 2.375”–8.625” OD

Flanging: 21,3–219,1 mm | .840”–8.625” OD

Pipe diameters: 21,3–219 mm | .840”–8.625” OD

Material: Stainless Steel, Copper, Carbon Steel, Aluminum, CuNi

Machine type: Industrial machines

Process: End forming

With the T-DRILL F-200 flanging machine lips and flanges are formed directly on the end of the pipe – a system that saves up to 40 % in time and costs compared with traditional weld neck flange connections.

F-200 meets the major requirements of the chemical and food-processing industries, and of shipbuilding and pipe fabrication in general.

If you are interested in receiving a customized offer, you can find our contact information at the link below.

You can also send a pipe specification sheet through our contact form.

COMPARISON: Welded Fittings vs T-DRILL Collaring & Flanging

CUT COSTS, IMPROVE EFFICIENCY, AND SAVE A MILLION PER YEAR WITH T-DRILL METHOD.

| F-200 | Value |

|---|---|

| Mains supply | 200–240 V / 50 Hz /60 Hz, 3-phase 400–480 V / 50 Hz /60 Hz, 3-phase |

| Fuse | Min 3 x 50, Max 3 x 125 A (200–240 V) Min. 3 x 35, Max. 3 x 100 A (400–480 V) |

| Power supply | 10 kW |

| Air pressure | 6 bar (600 kPa) *) | 87 psi *) |

| Air consumption | 20 l/min *) |

| Oxygen | 2–5 bar (200–500 kPa *) | 29–72 psi * |

| Propane | Max. 2 bar * | 29 psi * |

| Hydraulic pressure | Max. 120 bar | 1740 psi |

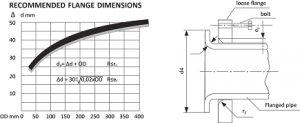

| Flanging range | 21,3–219 mm | .840”–8.625” OD |

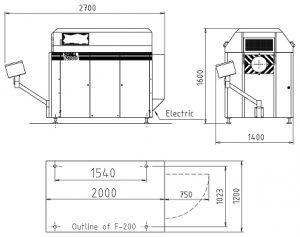

| Machine dimensions | 1 700 x 1 120 x 1 370 mm | 67'' x 44'' x 54'' (L x W x H) |

| Package dimensions | 1 700 x 1 120 x 1 370 mm | 67'' x 44'' x 54'' (L x W x H) |

| Net weight | 2,700 kg | 5,952 lbs. |

| Gross weight | 3,200 kg | 7,055 lbs. (in wooden case) |

| *) Required only with hot forming system | |

Note! Above values are intended as a guide only.

*) Required only with hot-forming system

Share on social media