With T-DRILL flanging technology, the flange joint can be fabricated very quickly and totally without welding. Therefore, for example X-ray inspection is not needed after flanging.

T-DRILL flanging technology has been widely in use in several industries (e.g. Process, Pulp and Paper, Chemical, Food and Brewery, Shipbuilding, Water and Waste water, District heating and cooling, Ventilation and Stainless steel piping systems) already +30 years. Hence there are more than 100 of satisfied customers existing.

This T-DRILL technology has relevant standard approvals and the flange lips are formed according to dimensions defined by these standards.

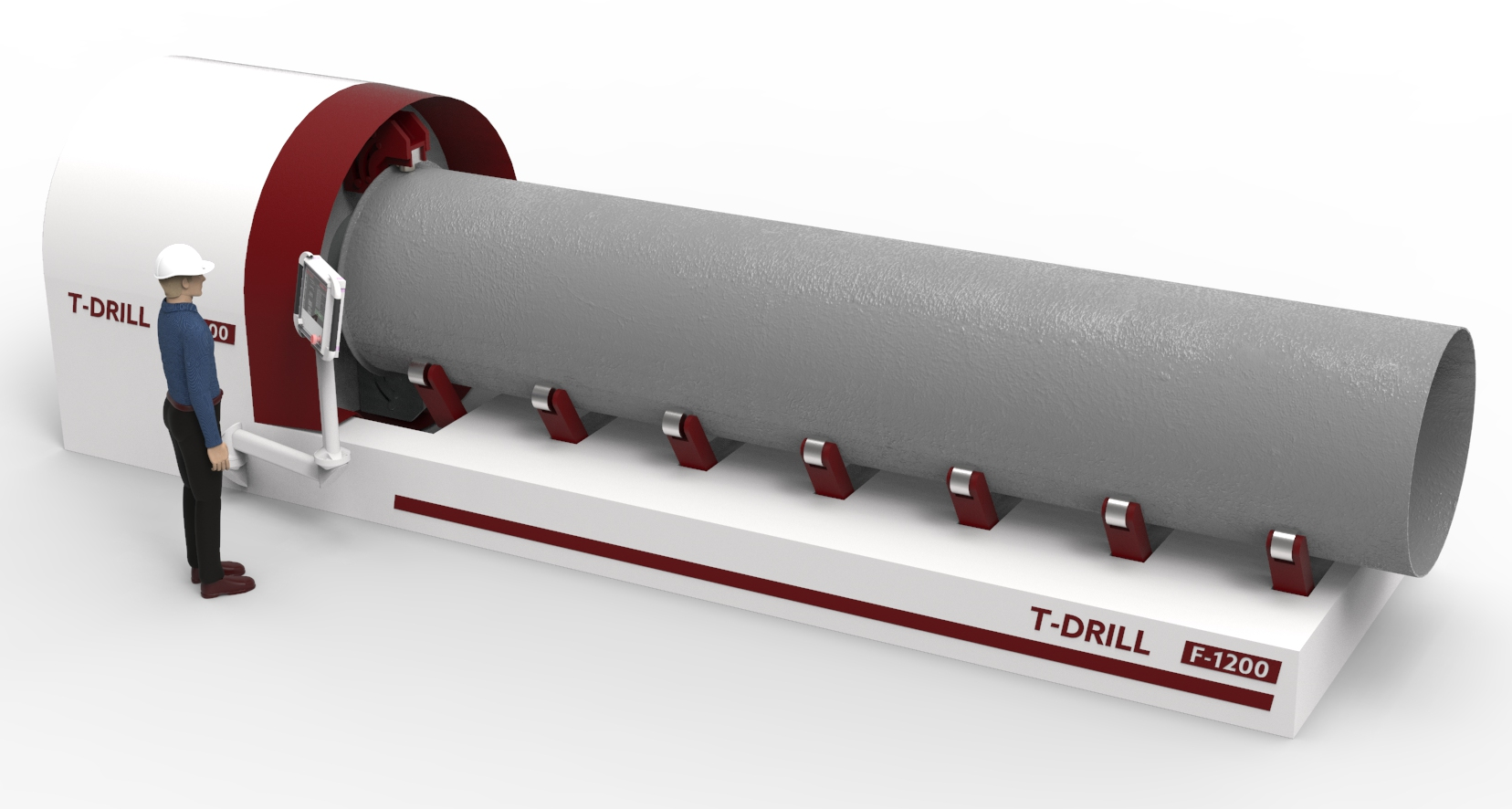

In addition to T-DRILL standard flanging machines (up to DN 400 pipes), we are able to offer special flanging machines even for ~Ø1200 mm pipes or larger.

E.g. HVAC and aviation are typical industries where these larger special Flanging machines are needed.

In addition to 90 degree flanges, this new system will also provide e.g. 35-60 degrees flares.

Share on social media