Additional Information

Collar sizes:

Drilling/collaring/trimming: Ø12–30 mm | O.D. ½”–1 1⁄8″

Elliptical pilot hole:Ø17,2–30 mm | O.D. ¾”–1 1⁄8”

Drilling/collaring: Ø6–28 mm | O.D. ¼”–1 1⁄8″

Run tube sizes: Ø8–30 mm | O.D. 5⁄16″–1 1⁄8″

Pipe material: Steel, Stainless steel, Aluminium, Copper, Copper-Nickel

Machine type: Industrial machines

Process: Collaring

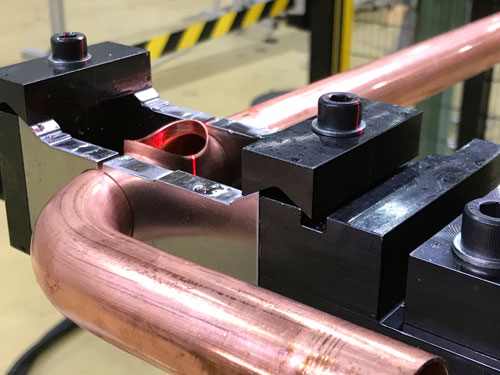

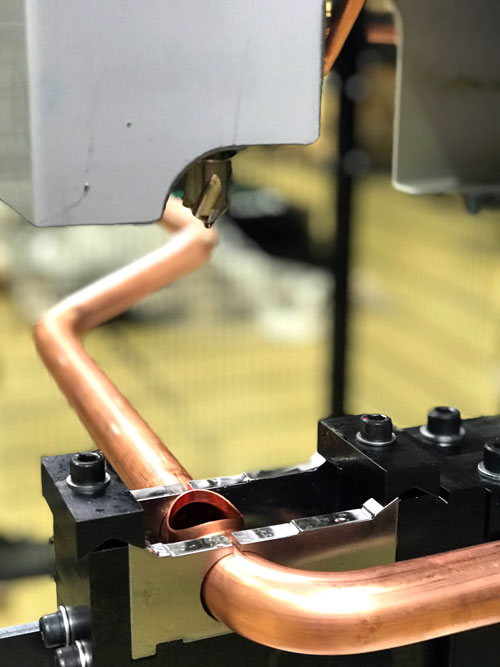

T-DRILL S-28 is a slim collaring machine that is designed especially for bent tubes with tight curves when collaring machine S-56 is not suitable.

S-28 is equipped with the newest technology, robust construction, and clamping. Accurate servo-controlled movements ensure the best possible collaring result.

S-28 is capable of producing collars for copper, aluminum, steel, stainless steel, brass, and other malleable materials. Collar sizes from 6 to 28 mm.

If you are interested in receiving a customized offer, you can find our contact information at the link below.

You can also send a pipe specification sheet through our contact form.

COMPARISON: Welded Fittings vs T-DRILL Collaring & Flanging

CUT COSTS, IMPROVE EFFICIENCY, AND SAVE A MILLION PER YEAR WITH T-DRILL METHOD.

Use the calculator to see how much you can save with T-DRILL method.

| S-28 | Value |

|---|---|

| Collaring range (Drilling/collaring/trimming) | Ø12–30 mm | O.D. ½"–1 1⁄8" |

| Collaring range (Elliptical pilot hole) | Ø17,2–30 mm | O.D. ¾"–1 1⁄8” |

| Collaring range (Drilling/collaring | Copper & Aluminium) | Ø6–28 mm | O.D. 1/4"–1 1⁄8" |

| Materials for work piece | Steel, Stainless Steel, Aluminum, Copper, CuNi |

| Diameter of run tube | Ø8–30 mm | O.D. 5⁄16"–1 1⁄8" |

| Compressed air supply | 6 bar | 87 psi |

| Air consumption (basic machine only) | 55 l/min | 14.5 GPM |

| Rated power | 4 kW |

| Fuses | 16 A |

| Supply voltage | 200–240V / 400–480V 50Hz/60Hz, 3 Phase |

| Machine dimension H x W x D | 1945 x 2360 x 2085 mm | 77" x 93" x 82" |

| Machine weight w/o electric cabinet | 1945 x 2360 x 2085 mm | 77" x 93" x 82" |

Note! The above values are intended as a guidance only.

Share on social media