S-56

Collaring range: Ø10–58 mm | O.D. 3⁄8”–2 ¼”

Run tube sizes: Ø8–114,3 mm | O.D. 5⁄16″–4 ½”

Pipe material: Steel, Stainless steel, Aluminium, Copper, Copper-Nickel

Machine type: Industrial machines

Process: Collaring

S-56 COLLARING MACHINE FOR PRODUCING T-OUTLETS FOR BOTH STRAIGHT AND BENT TUBES

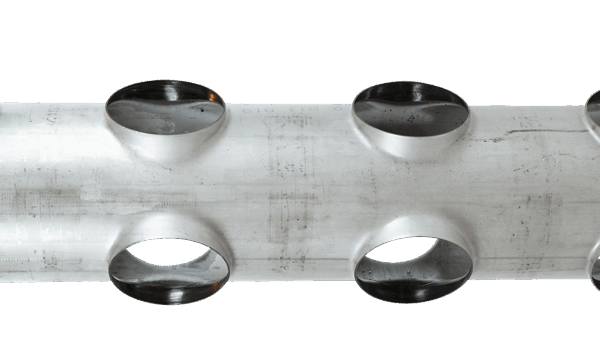

T-DRILL S-56 is a highly effective collaring machine for producing T-outlets for brazed and welded joints. The machine is designed for both straight and bent tubes. The S-56 produces quality collars up to 54 mm (O.D. 2 1/8”) with a round pilot hole and 60,3 mm (O.D. 2 1/4″) with an elliptical pilot hole. It is ideal for producing collars in steel tubes, but also suitable for all malleable materials (steel, stainless steel, aluminum, copper & copper-nickel).

The T-DRILL S-56 collaring process is fully automated and the drilling & trimming processes are optimized. The specially designed S-56 collaring heads enables three types of process:

- Drilling/Collaring/Trimming – Used for butt weld method where branch tube is put on top of collar.

- Elliptical pilot hole – Used for butt weld method. An elliptical pilot hole is done beforehand with laser, plasma, milling or with punching machine. Enables 1:1 collaring.

- Drilling/Collaring – Used for lap joint method where branch tube is put inside of the collar.

Being an Industry 4.0 ready machine utilizing the latest technology, the S-56 is very versatile and easily customized to fit specific customer needs. The machine is easy to program and use, featuring a user-friendly GUI Interface with a color touch panel, adjustable machining parameters, and fine-tuning of motion profiles. A wide range of feeding tables and automated systems are available for improved manifold production efficiency.

S-56 can also be integrated into flexible manufacturing systems:

S-56 ACCESSORIES

Manual Feed Table MFT

Adding a feed table to S-56 improves the manifold / collector production efficiency. The Manual Feed Table (MFT) enables fast pipe positioning for the operator.

S-56 APPLICATIONS

Stainless process pipes

Process piping in stainless steel frequently results in a need for multiple outlets in a manifold. There is no better way to manufacture such a manifold than the T-DRILL process. By eliminating two welded joints, the system minimizes costs and increases profit while offering improved quality.

The S-56 offers great advantages in the following industries:

- Food & Dairy industry

- Pharmaceutical industry

- Chemical industry

- Brewery industry

- Fire protection (sprinkler systems)

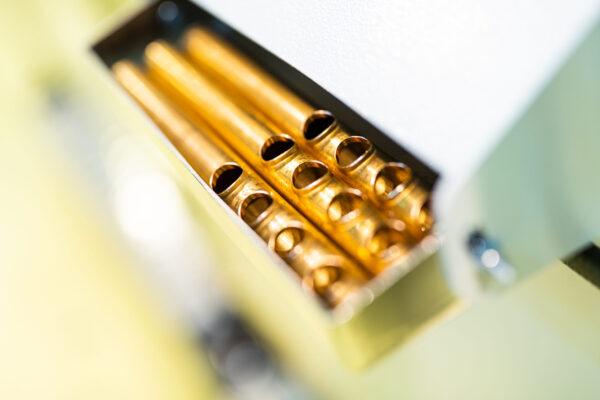

HVACR industry

In the HVAC industry, T-DRILL machines are typically used in the manufacture of tubular components found in air conditioning/ refrigeration, heat pumps, heat recovery and heat exchanger manufacturing. The S-56 is well suited for these applications and many more – offering the most reliable tube joints of top quality.

Automotive industry

T-DRILL’s reliable T-joining has a vital importance for automotive tube applications, because every vehicle is subject to severe vibrations. As T-DRILL’s extruded outlets are formed outside of the main run tube, it also minimizes the flow restrictions.

The S-56 is ideal for efficient fabrication of the following:

- Engine a/c systems

- Fuel rail and high pressure diesel components

- Exhaust cross-over applications

- Vapor recovery systems

- Battery cooling for electric vehicles

TECHNICAL DETAILS

| Collaring range (Drilling/collaring/trimming) | Ø10–58 mm | O.D. 3⁄8"–2 ¼" |

| Collaring range (Elliptical pilot hole) | Ø17,2–60,3 mm | O.D. ¾"–2 ¼” |

| Collaring range (Drilling/collaring | Copper & Aluminium) | Ø6–54 mm | O.D. 1/4"–2 1/8" |

| Materials for work piece | Steel, Stainless Steel, Aluminum, Copper, CuNi |

| Diameter of run tube | Ø8–114,3 mm | O.D. 5⁄16"–4 ½" |

| Compressed air supply | 6 bar | 87 psi |

| Air consumption (basic machine only) | 55 l/min | 14.5 GPM |

| Rated power | 4 kW |

| Fuses | 16 A |

| Supply voltage | 200–240V / 400–480V 50Hz/60Hz, 3 Phase |

| Machine dimension H x W x D | 1991 x 800 x 1187 mm | 78" x 31" x 47" |

| Machine weight w/o electric cabinet | 536 kg | 1179 lbs |

Note! The above values are intended as a guidance only.