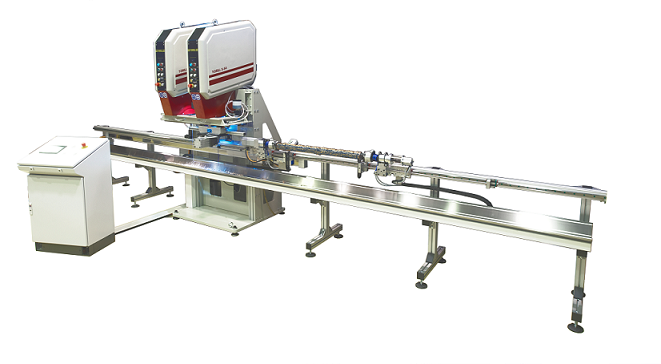

T-DRILL S-54 AFT is the fastest industrial collaring machine in the world. The entire process (pilot hole drilling, collaring and trimming) can be done with one tool, in one process – it takes seconds, not minutes.

Many times e.g. in HVAC industry or steel heat exchangers, there are two hole sizes in one pipe to be collared – one bigger inlet and many smaller outlets. In this kind of application T-DRILL S-54 “Double Head AFT” is a perfect solution – with two working tools, both hole sizes can be collared and trimmed in one machine. After this T-DRILL process, the pipe is ready for butt welding.

Sometimes the customer has an extremely high production volume, with also 1:1 collars. Then the collaring process can be done even faster, if customer pre-cuts the pilot holes before the pipes comes to T-DRILL machine. In such a case one collar fabrication time can be even less than 10 seconds!

Share on social media