T-DRILL Customized Tube Fabrication Solutions

T-DRILL offers flexible customized tube and pipe fabrication solutions for a vast variety of tubing needs. As a pioneer in the field, T-DRILL has the capability to create special machinery solutions to meet its customer’s unique manufacturing requirements and to increase their productivity in a highly effective way. Here’s few examples:

Heavy Collaring Cell for SF6 switch-gear applications

An example of delivered SF6 switchgear project machine:

Principle:

In an electric power system, switchgear is composed of electrical disconnect switches, fuses or circuit breakers used to control, protect and isolate electrical equipment and high-voltage power lines.

In SF6 switchgear, the current interruption in a high-voltage circuit breaker is obtained by separating two contacts in a medium gas, such as sulfur hexafluoride (SF6).

According to customer needs, T-DRILL has developed the collaring cell for SF6 switchgear houses. After T-DRILL process, they are ready for next step (end flanges welding) in SF6 switch-gear production.

Key Features:

- SF6 house (Pipe) handling, turning and positioning according to customers work piece.

- T-DRILL heavy collaring process, maximum collar size ~850 mm (smaller model ~600 mm)

- Cutting of pilot holes and trimming of the collars by Plasma cutter or Cutting blades.

- Individual clamping molds for each run pipe/collar variant ensures the maximum quality.

- Suitable materials e.g. Carbon steel, Stainless steel, Aluminum.

- Pre-heating of a material by gas burners, if necessary.

- Applicable switchgear voltage classes e.g. 35kV, 110kV, 220kV, 500kv.

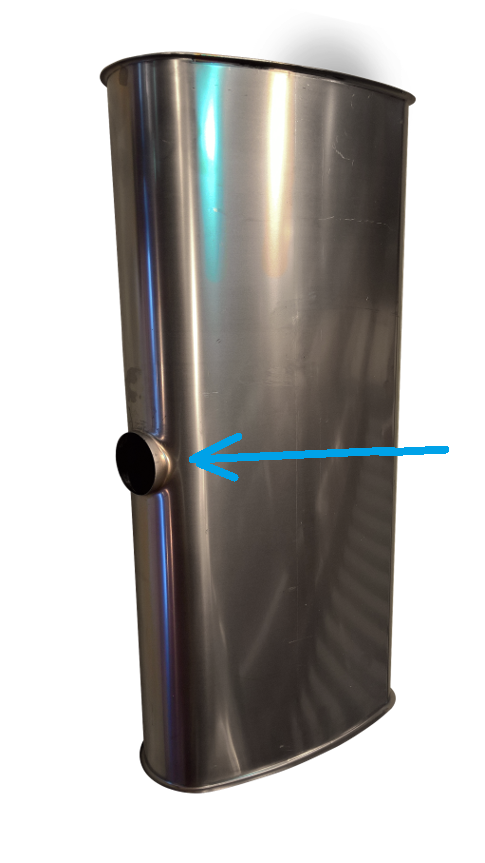

Collaring Machine for Automotive Silencer Mass Production

Principle:

In automotive silencer, there is outlet pipe for the exhaust gas. T-DRILL has created a special Collaring Machine for the cold forming of this hole. After T-DRILL process, customer will typically expand & weld the exhaust gas pipe to this hole fabricated by T-DRILL technology.

According to customer needs, T-DRILL will provide individual jigs for each model of exhaust silencer. The positioning and clamping is robust, quick & accurate.

According to customer needs, T-DRILL will provide individual jigs for each model of exhaust silencer. The positioning and clamping is robust, quick & accurate.

Change over time from one silencer model to another takes minutes, not hours. Typical cycle time of the exhaust silencer production line is 20-30 seconds. In this time frame, all T-DRILL processes can be done, including the work piece change time.

Key Features:

- Movable & centralizing clamp. After collaring process, the clamp will automatically move out from the collaring position to unload/load position.

- The machine is equipped with the pair of light cell for the operator safety, CE mark.

- Individual clamping jigs for each silencer model.

- Quick change over time for clamping jigs and collaring tools.

- One operator needed to operate this machine.

- The machine identifies that the silencer is loaded in a right way prior the collaring process.

- Suitable for Ferritic- and Austenitic Stainless Steel, single- or two material layers.

- Prior the T-DRILL collaring process, customer typically cuts Pilot holes by laser or punching.

- Suitable for common silencer models

- Collar (hole) inner diameter, max ~Ø80 mm.

- Connection for remote service/update.

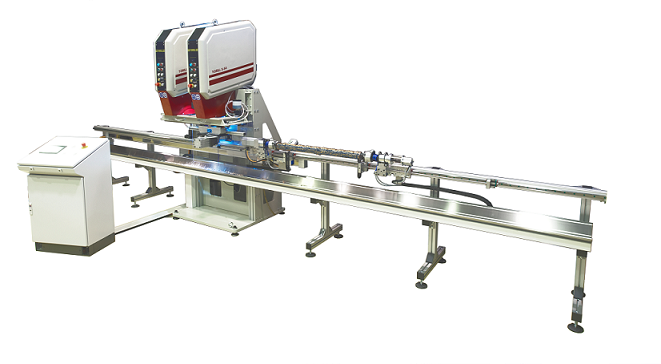

High-Speed Automatic Collaring System for Steel Pipes | S-54 Double AFT

Principle:

T-DRILL S-54 AFT is the fastest industrial collaring machine in the world. The entire process (pilot hole drilling, collaring and trimming) can be done with one tool, in one process – it takes seconds, not minutes.

Many times e.g. in HVAC industry or steel heat exchangers, there are two hole sizes in one pipe to be collared – one bigger inlet and many smaller outlets. In this kind of application T-DRILL S-54 “Double Head AFT” is a perfect solution – with two working tools, both hole sizes can be collared and trimmed in one machine. After this T-DRILL process, the pipe is ready for butt welding.

Sometimes the customer has an extremely high production volume, with also 1:1 collars. Then the collaring process can be done even faster, if customer pre-cuts the pilot holes before the pipes comes to T-DRILL machine. In such a case one collar fabrication time can be even less than 10 seconds!

Key Features:

- Fastest industrial collaring machine in the world

- Automatic Collaring System to prepare steel pipes for butt welding

- Two Collaring Units means extra fast process, since two different collar diameters can be produced in one machine

- In many applications, only two collar diameter are needed in one pipe and after this one T-DRILL process, the pipe is ready for butt welding

- Extremely fast 1:1 collaring (from pre-cut pilot holes)

- Fast and accurate positioning system for pre-cut elliptical pilot holes

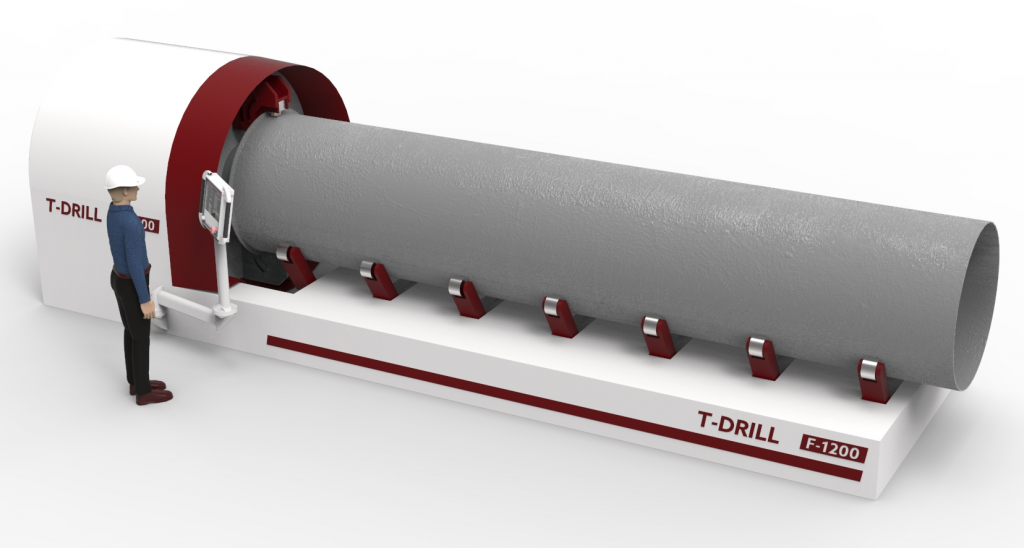

Special Flanging Machines for Larger Tubes

Principle:

With T-DRILL flanging technology, the flange joint can be fabricated very quickly and totally without welding. Therefore, for example X-ray inspection is not needed after flanging.

T-DRILL flanging technology has been widely in use in several industries (e.g. Process, Pulp and Paper, Chemical, Food and Brewery, Shipbuilding, Water and Waste water, District heating and cooling, Ventilation and Stainless steel piping systems) already +30 years. Hence there are more than 100 of satisfied customers existing.

This T-DRILL technology has relevant standard approvals and the flange lips are formed according to dimensions defined by these standards.

In addition to T-DRILL standard flanging machines (up to DN 400 pipes), we are able to offer special flanging machines even for ~Ø1200 mm pipes or larger.

E.g. HVAC and aviation are typical industries where these larger special Flanging machines are needed.

In addition to 90 degree flanges, this new system will also provide e.g. 35-60 degrees flares.

Key Features:

- Flange joint can be executed totally without welding -> saves time, increase quality, no X-ray inspection, no stock fitting = much cost savings

- No forming tool change, all pipe Ø sizes can be formed with same tool

- For excellent quality, Individual pipe clamps needs to be changed for each pipe diameter

- Suitable for all malleable materials e.g. Stainless steel, Carbon steel, Copper, CuNI, Aluminum.

- Heating of material by gas burners, if necessary (especially with carbon steel)

- Applicable for pipe wall thicknesses max ~10 – 12 mm steel (softer material can be greater)

- Only “Vanstone” Flanging machine on the Market with capacity over 16 inch pipe diameter