Additional Information

Collar sizes: 8–54 mm | NS ½” – 2”

Run tube sizes: 15–108 (163,8 mm) | NS ½” – 4” (6″)

Pipe material: Copper, Copper / Nickel

Work cycle time: 15–60 sec

Machine type: Portable tools

Process: Collaring

The Heavy Duty T-DRILL T-65 is a powerful member in the T-DRILL tool family of copper tubes. Having a capacity up to 54 mm (NS 2”) out of run tubes up to 108 mm (NS 4”) (with optional retrofit kit even up to 168,3 mm run tubes) will make you more profitable and competitive. If a comparison is made between the installed cost of a tee fitting and T-DRILL joint you will see an improved profit that approaches 70%. This is documented in most any labor calculator in use.

CUT COSTS – IMPROVE QUALITY – INCREASE PROFIT

More about the T-DRILL certification test

COMPARE YOURSELF!

Click the selected Excel chart below and use your own figures to replace the red ones. The costs by each method will be calculated automatically.

Click to download the Excel files.

Cost Comparison between Capillary Fittings and T-DRILL Method

Cost Comparison between Press Fittings and T-DRILL Method

CUT COSTS, IMPROVE EFFICIENCY, AND SAVE A MILLION PER YEAR WITH T-DRILL METHOD.

COMPARISON: Welded Fittings vs T-DRILL Collaring & Flanging

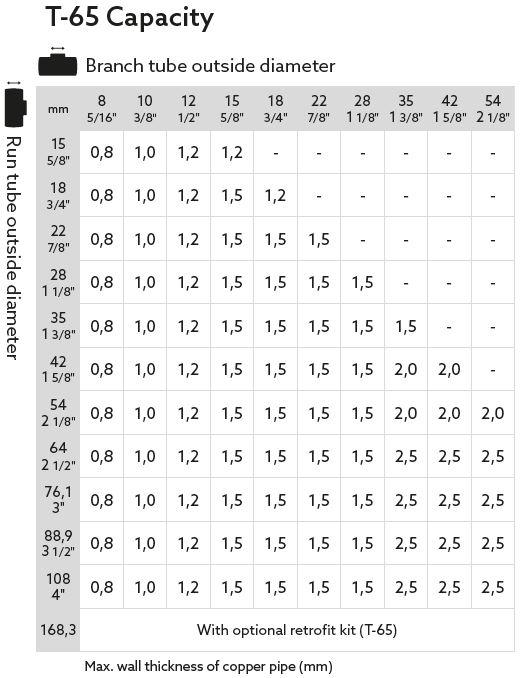

Capacity Chart for Maximum Run Tube Wall Thickness (run tube size on the left and branch size on the top)

Technical Information

| T-65 | Value |

|---|---|

| Tee diameter | 8–54 mm | NS ½” – 2” |

| Run tube diameter | 15–108 (163,8 mm) | NS ½” – 4” (6″) |

| Max. wall thickness | See capacity chart | K, L, M tubing |

| Material | Copper |

| Cycle time | 15–60 sec |

| Spindle rotation speed | 0–500/50 rpm |

| Noice level | 82,5 dB (A) |

| Vibration | less than 2,5 m/s2 |

| Dimensions of the unit | 22.4'' x 4.9'' x 7.0'' (L x D x H) |

| Weight of the unit | 5,4 kg | 12 lbs |

| Supply voltage | 230V / 50Hz 120V / 60 Hz 110V / 50 Hz |

Share on social media