Additional Information

Collaring sizes: 17 – 114.3 mm (3/8” – 4”)

Run tube sizes: 21,3 – 114,3 mm (1⁄2 – 4”)

Rated power: 15 kW

Machine type: Industrial machines

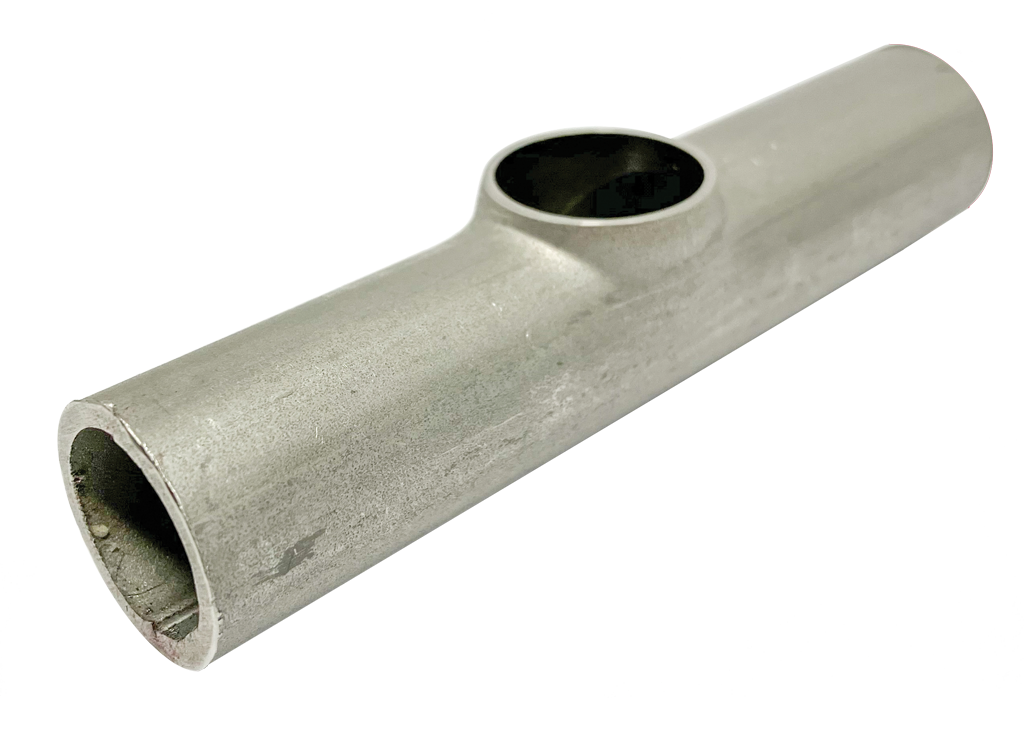

Process: Collaring

Completely new Tube Branching Center for fastest T-DRILL T-fitting manufacturing ever, up to 160 T-fittings per hour.

TBC-115 has a turntable with three machining units, which allow

the three steps of the process to be done simultaneously:

Automatic adjustment of collaring tools according to collar size within the adjustment range of each collaring head. Emulsion lubrication for milling and trimming process results in a clean tube without chips stuck to it. TBC-115 is Industry 4.0 and online cloud system TD-Vault ready.

If you are interested in receiving a customized offer, you can find our contact information at the link below.

You can also send a pipe specification sheet through our contact form.

COMPARISON: Welded Fittings vs T-DRILL Collaring & Flanging

CUT COSTS, IMPROVE EFFICIENCY, AND SAVE A MILLION PER YEAR WITH T-DRILL METHOD.

Use the calculator to see how much you can save with T-DRILL method.

| TBC-115 | |

|---|---|

| Collar sizes | 17 – 114.3 mm (3/8” - 4”) |

| Run tube sizes | 21,3 – 114,3 mm (1⁄2 – 4”) |

| Rated power | 15 kW |

Note! The above values are intended as a guidance only.

Share on social media