F-420e

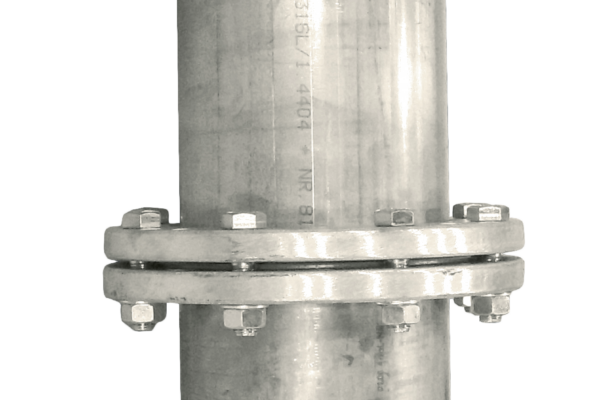

Pipe to be flanged: Ø21,3 – 419,0 mm | 1 1/3″– 16 ¹/₂”

Pipe material: Copper, CuNi, Carbon steel, Stainless steel, Aluminium

Machine type: Industrial machines

Process: Flanging

F-420e FULLY ELECTRIC FLANGING MACHINE

Globally the first of its kind, T-DRILL’s revolutionary Flanging Machine F-420e, is by far the most advanced flanging machine on the market – implemented with entirely programmable servo technology. It is fully electric.

T-DRILL F-420e guarantees the highest possible workpiece quality and repeatability, including the best quality-related software adjustments on the market. All adjustments by the program – ensure the fastest set-up time, also when switching from one pipe dimension to another.

The machine is easily operated to achieve maximal quality with minimal operator effect. Also maintenance is really easy (no hydraulics), including mainly cleaning and lubrication.

F-420e is suitable for malleable materials, such as copper, carbon steels, stainless steel, aluminium, pipe diameters up to 420 mm (16”), wall thickness up to 5 mm with cold forming and 9 mm with hot forming (carbon steel).

TECHNICAL DETAILS

| Pipe to be flanged | Ø21,3 – 419,0 mm |

| Materials to be formed | Copper, CuNi, carbon steel, stainless steel, aluminum |

| Max. wall thickness | SST 5 mm, excluding small tubes Hot forming for carbon steels up to 9 mm |

| Operating voltage/Power | 380–440 V / 50/60 Hz - 3-phase/ 12 kW |

Note! The above values are intended as a guidance only.