SPM-115

Spinning range: Ø8–115 mm | 5/16” – 4-1/8”

Pipe material: Copper

Machine type: Industrial machines

Process: End-forming

FULLY AUTOMATIC SERVO-CONTROLLED TUBE END SPINNING MACHINE SPM-115

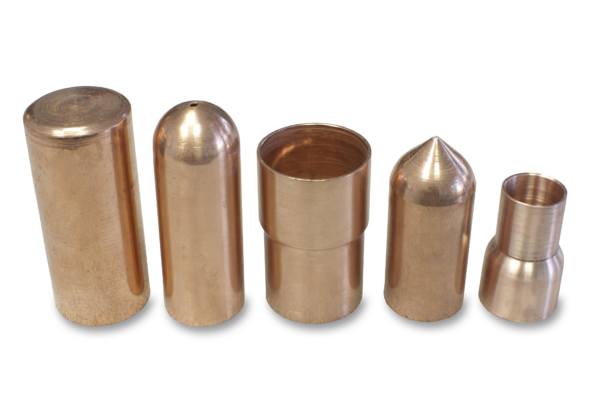

T-DRILL’s new Fully automatic servo-controlled Tube End Spinning Machine SPM-115 is designed for flat closing of copper and brass tubes. The machine has a fast cycle time, as the typical process time is only ~ 20–45 seconds depending on tube specification.

Process:

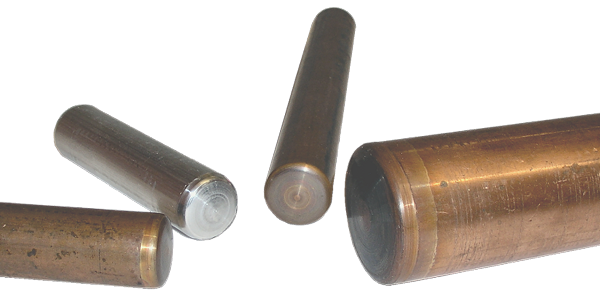

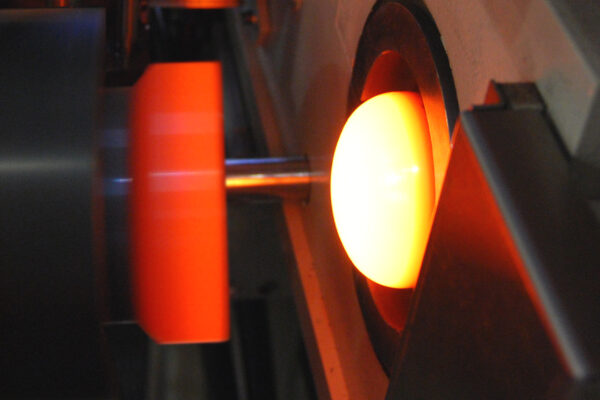

Tube is loaded, the clamps are closed, and tube is held stationary. Rotating tool is automatically fed against the tube end. The friction between the rotating tool and the tube heats the tube end and rapidly forms it. System offers rapid set-up and change-over: clamps are changed according to the tube size, the program is selected from the library and the machine makes the correct adjustments automatically. The user-friendly GUI with color touch panel guides the operator visually step by step.

The operation is completely electric, without hydraulics and pneumatics. This results in energy efficient, low loss process with high repeatability. The SPM-115 is also very quiet with less than 75 dB noise level.

TECHNICAL DETAILS

| Tube material | Copper & Brass (other materials, please consult T-DRILL) |

| Tube size | Ø 8–115 mm | 5/16” – 4-1/8” |

| Max. wall thickness | 3,4 mm |

| Operating voltage | 200–240 V / 50–60 Hz 380–480 V / 50–60 Hz |

| Nominal power | 17,5 kW |

| Noise level | < 75 dB |

| Machine dimensions | 1565 x 850 x 1600 mm (h x w x d) w/o electric cabinet |

| Net weight | 1400 kg (electric cabinet included) |

Note! The above values are intended as a guidance only.