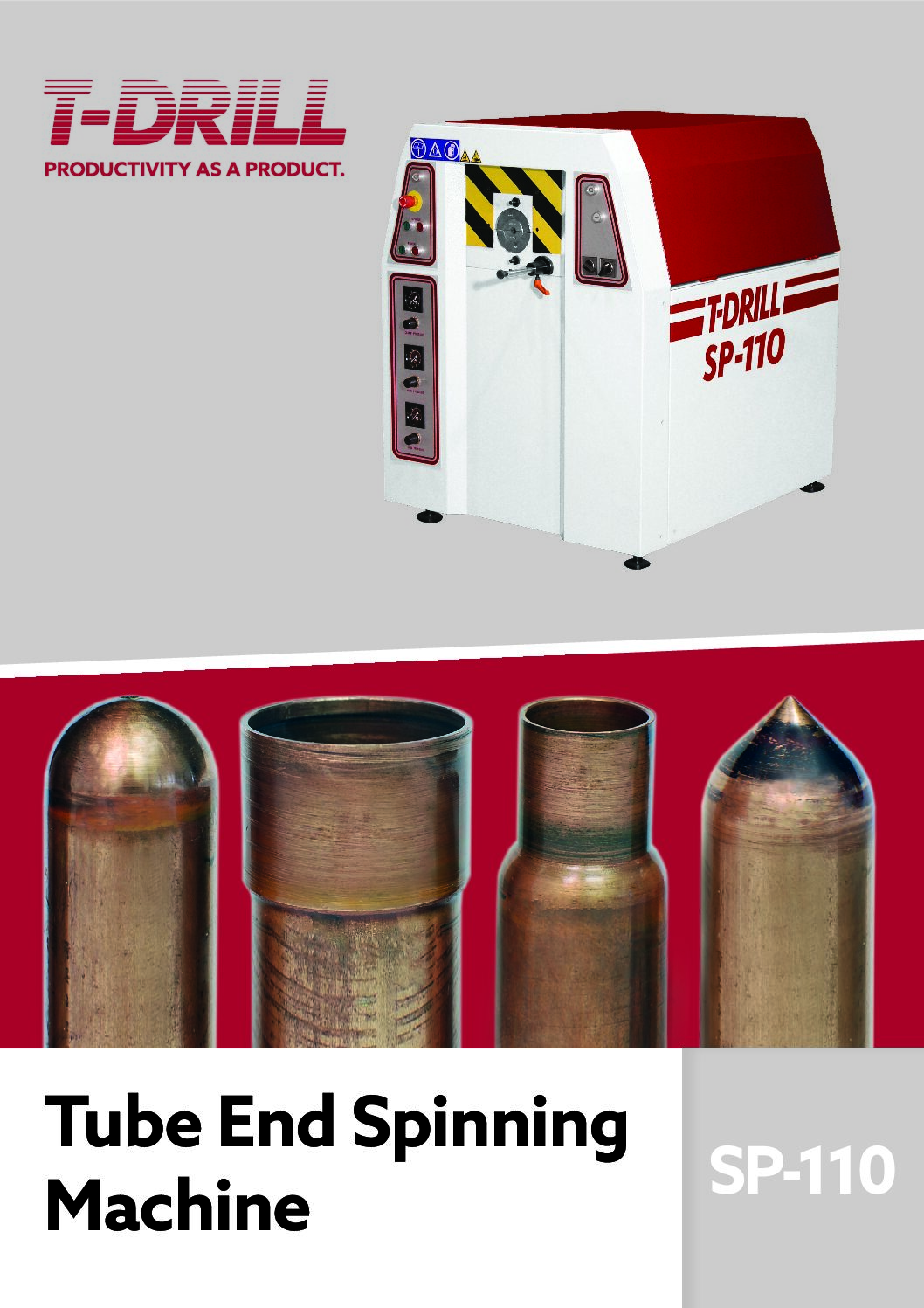

SP-110

Spinning range: Ø8–108 mm | 5/16” – 4-1/8” O.D.

Pipe material: Copper

Machine type: Industrial machines

Process: End-forming

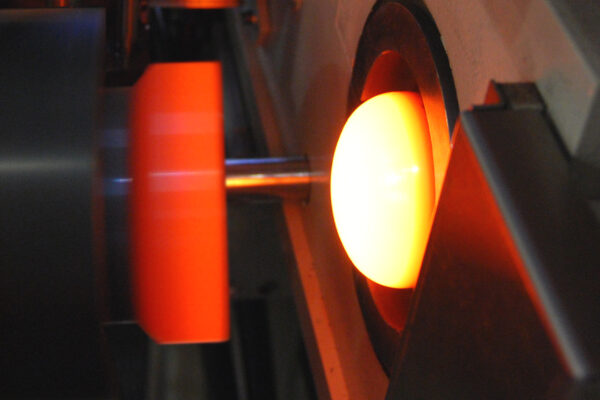

FULLY AUTOMATIC TUBE END SPINNER

SP-110

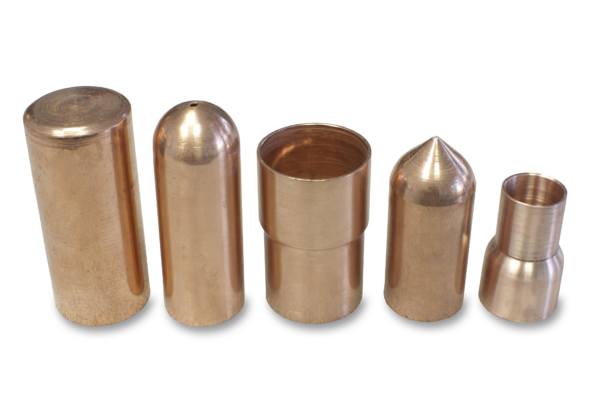

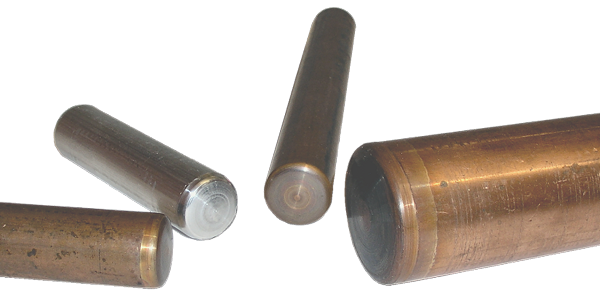

T-DRILL tube end spinner is a solution for closing, reducing and expanding copper tubes. Maximum reduction is 70%. The SP-110 is suitable for diameter 8–108 mm (5/16” – 4-1/8” O.D.) tubes. Typical applications are different tubes for HVAC equipment. T-DRILL spinners are fully automatic.

Advantages of T-DRILL Tube End Spinners:

- Economical: Reduced costs of fittings and brazing materials

- Simple: No need for or inventory of costly fittings

- Fast: Reduced Labor

- Quality: Improved product integrity as leak points are eliminated

TECHNICAL DETAILS

| Mains supply | 200-240 V / 50-60 Hz, 3-phase, 380-480 V / 50-60 Hz, 3-phase |

| Main fuse | Max. 3 x 80 A |

| Motor | 18,5 kW |

| Air pressure | 6–8 bar |

| Air consumption | 850 Nl/min |

| Closing diameters | Ø8–108 mm | 5/16” – 4-1/8” O.D. *) |

| Reduction diameters | Ø8–108 mm | 5/16” – 4-1/8” O.D. *) |

| Expanding diameters | Ø8–67 mm | 5/16” – 2-5/8” O.D. *) |

| Max. wall thickness | 3 mm | 1/8” |

| Machine dimensions | 1500 x 925 x 1170 mm | 5ft x 3ft x 4ft (L x W x H) |

| Package dimensions | 1800 x 1100 x 1450 mm | 6ft x 4ft x 5ft (L x W x H) |

| Net weight | 550 kg | 1200 lbs |

| Gross weight | 770 kg | 1700 lbs |

*) Minimum spinning O.D. to be confirmed case by case

Note! The above values are intended as a guidance only.