T-115

Collaring range: Ø19–114,3 mm | max. 4″

Run tube sizes: Ø33,7–323,9 mm | 1″– 12″

Pipe material: Aluminium, Copper, Stainless steel, Steel

Machine type: Industrial machines

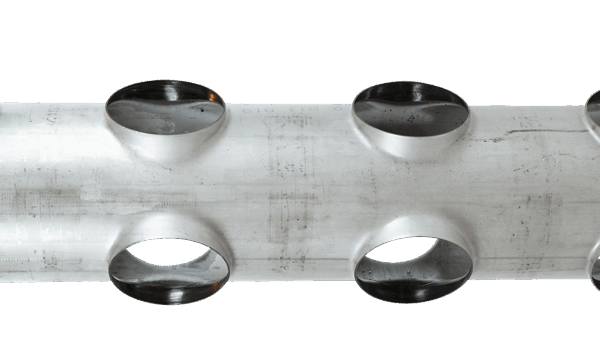

Process: Collaring

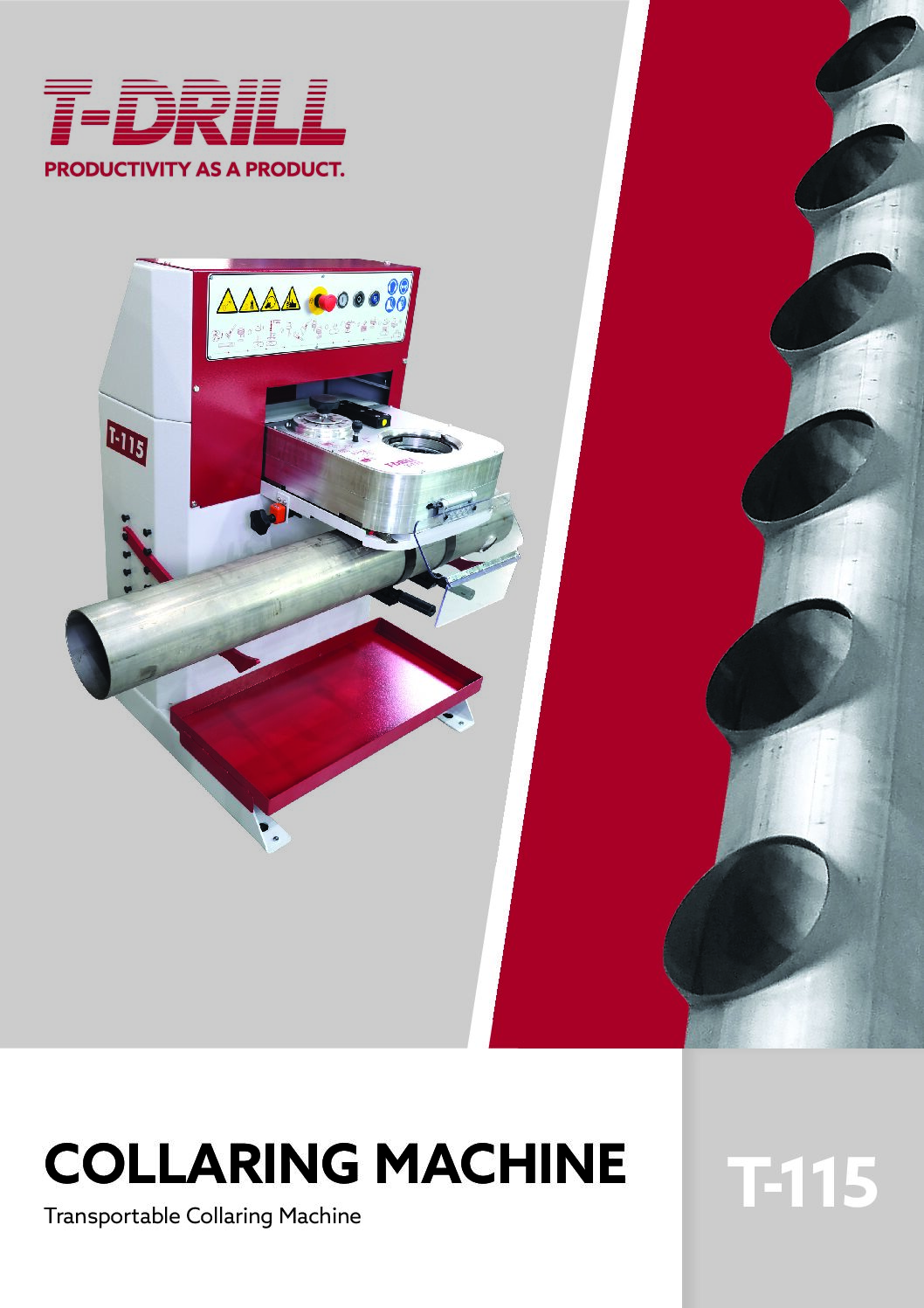

T-115 TRANSPORTABLE COLLARING MACHINE

The transportable T-DRILL T-115 Collaring Machine produces extruded outlets for branch connections directly on run tubes 33,7–323,9 mm (1’’–12’’) with branch tube diameter up to 114,3 mm (4’’). The entire process from pilot hole milling to trimming is carried out in three steps on a single workstation.

The T-115 machine is effortless to operate: the tools are adjustable for different branch pipe sizes, and the operation panel provides simple step-by-step instructions for starting and stopping pilot hole milling, collaring and trimming cycles.

The T-115 is only 800 mm (32’’) wide and designed for easy moving with a manual or motorized forklift. The delivery package includes also a convenient Tool Table with tool holders for easier machine usage and tool service.

T-115 is an ideal solution for both factory and on-site use for various industries, such as:

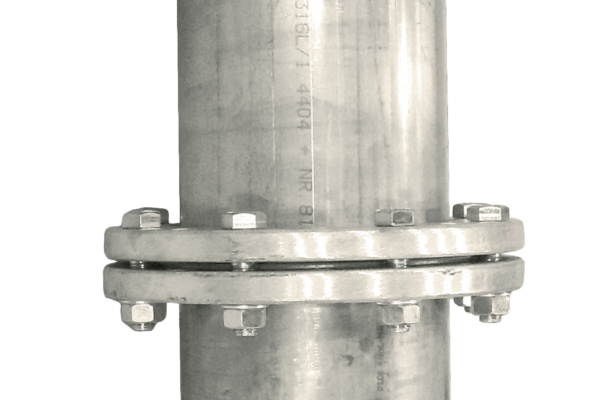

- Stainless Steel Enterprises (e.g. pumps, valves, Food & Dairy, Water Treatment, Pharmaceutical & Chemical industries)

- HVAC (e.g. heat exchangers, air pumps, radiators)

- Shipbuilding (e.g. air handling, clean & waste water, ballast water, engine tubes)

- Automotive & Aviation

- Special Applications

The T-115 collaring system consists of:

- T-115 collaring machine

- Pilot hole milling tool

- Collaring tools (with forming pins + pin holder according to collar diameters)

- Trimming tool

- Clamping tools according to run pipe diameters

- Tool Table with tool holders

The pilot hole tool, collaring tools and trimming tool are stored on the Tool Table. The tool holders can be used for tool setting. The buttons of the operation panel are used for starting and stopping pilot hole milling, collaring and trimming cycles.

TECHNICAL DETAILS

| Material to be formed | Aluminum, Copper, Stainless steel, Carbon Steel |

| Collar diameter | Ø 19–114,3 mm | .840” – 5.00” O.D. |

| Diameter of the run pipe | Ø33,7–323,9 mm | 1.315” – 12.750” O.D. |

| Max. wall thickness | See capacity chart |

| Sound level | Max. 78 dB |

| Operating voltage | 200-240 V / 50 Hz /60 Hz, 3-phase 400-480 V / 50 Hz /60 Hz, 3-phase |

| Fuses | 16 A |

| Measures of the unit | 820 x 910 x 1230 mm | 32,3 x35,4 x 48,4” |

| Weight of the unit | 250 kg I 551 lbs (With tool table 360 kg) |

Note! The above values are intended as a guidance only.