T-850

Collaring range: Ø168–880 mm

Run tube sizes: Ø254–1430 mm

Pipe material: Aluminium, Carbon steel, Stainless steel, Steel

Machine type: Industrial machines

Process: Collaring

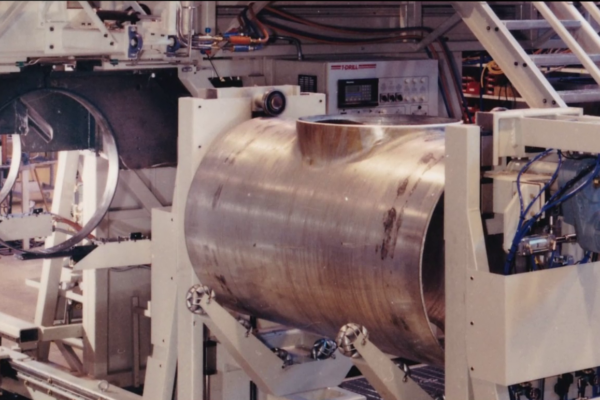

T-850 COLLARING STATION

Collaring by T-850 collaring machine is based on the patented T-DRILL-method. Both hot and cold forming procedures are possible. By cold forming it is possible to make collars in materials with cold forming properties, e.g. stainless steel pipes. Hot forming is used for mild steel pipes or aluminium alloy pipes. For hot forming the machine is equipped with heater arm and necessary control devices.

T-850 machine is semi-automatic: collaring, trimming and bevelling are made by an automatic work cycle, other functions are made manually by using push-buttons.

The machine is used in e.g. SF6 Gear Switch applications.

TECHNICAL DETAILS

| Collar diameter | 168–880 mm |

| Diameter of the tube to be collared | 265–1430 mm |

| Max wall thickness | See capacity charts |

| Materials to be collared | Stainless steel, Mild steel, Aluminium |

| Compressed air supply | 6–7 bar |

| Air consumption | 3 Nm3/h |

| Connected power | 51 kW |

| Size of fuses | 3 x 250 A |

| Dimensions of the unit | Depends on tube handling equipment; see also layout drawing |

| Weight | ~ 27 000 kg |

Note! The above values are intended as a guidance only.