T-115 Cu

Collaring range: Ø18–114,3 mm | NS 5/8” – 4”

Run tube sizes: Ø22–267 mm | NS 3/4” – 10”

Pipe material: Copper

Machine type: Industrial machines

Process: Collaring

T-115 Cu TRANSPORTABLE COLLARING MACHINE

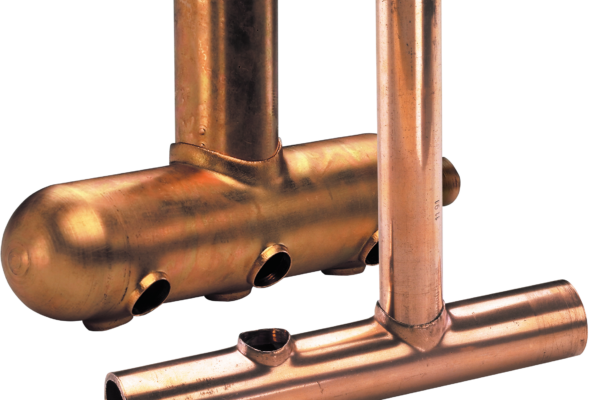

The transportable T-DRILL T-115 Cu Collaring Machine fits perfectly e.g. for the needs of heat exchanger manufacturers. The machine produces extruded outlets for branch connections in copper tubes within range 22–267 mm (⅞’’ – 10’’).

The T-115 Cu is easy to operate, as the operation panel provides simple step-by-step instructions and the delivery package includes a convenient Tool Table for easier machine usage and tool service. The machine is 800 mm (32’’) wide and designed for easy moving with a manual or motorized forklift. It is an ideal solution for both factory and on-site use.

The system consists of a pilot hole cutter for making a round pilot hole and collaring tooling for diameter range 18–108 mm (¾’’ – 4⅛). Each collaring tool (collaring head) is adjustable within a given range. Adjustment is made according to branch tube O.D. The machine drills the pilot hole and forms a collar on the tube. The branch tube is connected to the run tube by a brazed joint.

TECHNICAL DETAILS

| Collar diameter | Ø18–108 mm |

| Diameter of the run pipe | Ø22–267 mm |

| Maximum wall thickness | Max 5,38 mm |

| Material to be formed | Copper only |

| Sound level | Max 78 dB |

| Measures of the unit | See the layout drawing |

| Weight of the unit | 250 kg |

| Operating voltage | 200-240 V / 50 Hz /60 Hz, 3-phase 400-480 V / 50 Hz /60 Hz, 3-phase |

| Fuses | 16A |

| Motor | 2,2 kW |

Note! The above values are intended as a guidance only.