SEC-115

Collaring range: Ø17 – 114,3 mm | NS 3/8” – 4″

Run tube sizes: Ø33.7 – 273 mm | 1″ – 10″

Pipe material: Stainless steel, steel, copper, and aluminum

Machine type: Industrial machines

Process: Collaring

SEC-115 FULLY AUTOMATIC COLLARING MACHINE

Faster manifold collaring than ever before.

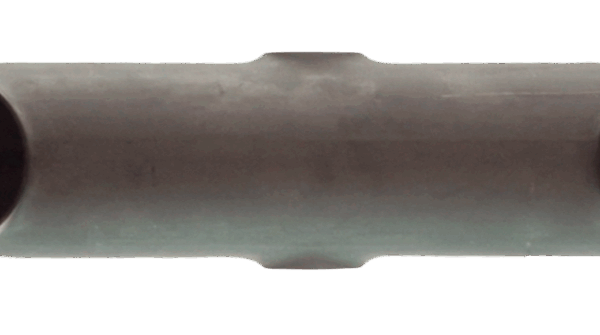

T-DRILL Fully Automatic Collaring Machine SEC-115 with automatic tool changer for five different collaring tools makes the production of manifolds with multiple collar diameters easier, faster, and more productive than ever before. SEC-115 is suitable for stainless steel, steel, copper, and aluminum manifold production.

The high-speed SEC-115 operates by moving according to the program along the tube length, while the pipe is rotated when needed.

The SEC-115 has a fully automatic collaring cycle:

1. Pilot hole milling

2. Collar forming and

3. Trimming for the collars to be welded

THE T-DRILL PROCESS

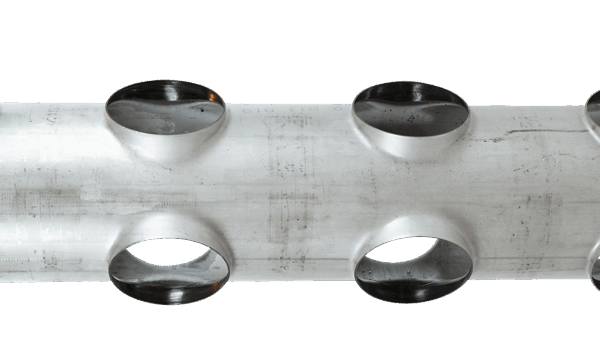

While the pilot hole milling unit works, the collaring unit collects simultaneously the correct collaring tool from the magazine and starts collaring instantly when the pilot hole is ready. The collaring tool is adjusted automatically according to the programmed collar diameter, so no manual tool adjustment is needed.

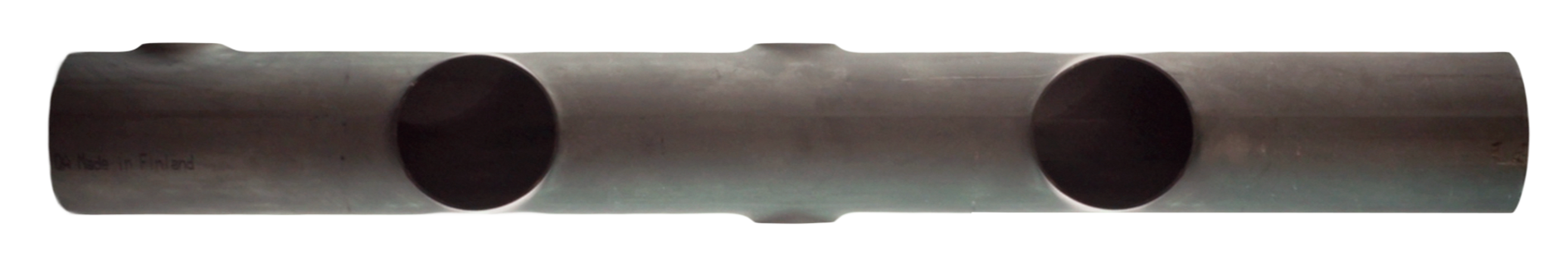

SEC-115 made this manifold in less than 10 minutes:

SEC-115 APPLICATIONS

Stainless steel manifolds especially with multiple collar diameters.

Potential industries for SEC-115

- Pump manufactures

- HVACR headers

- Level gauges

- Water treatment

- Food & Dairy industry

- Pharmaceutical industry

- Chemical industry

- Brewery industry

- Fire protection (sprinkler systems)

TECHNICAL DETAILS

| Collaring range | 17 – 114,3 mm / NS 3/8” - 4" |

| Run tube size | 33.7 – 273 mm / 1" – 10" |

| Rated power | 15 kW |

| Pipe material | Stainless steel, steel, copper, and aluminum |

Note! The above values are intended as a guidance only.