F-400

Pipe to be flanged: Ø(33,7 mm**) 42,4–419 mm|(1.315”**) 1.660”–16.00” OD

Pipe material: Stainless Steel, Copper, Carbon Steel, Aluminum, CuNi

Machine type: Industrial machines

Process: Flanging

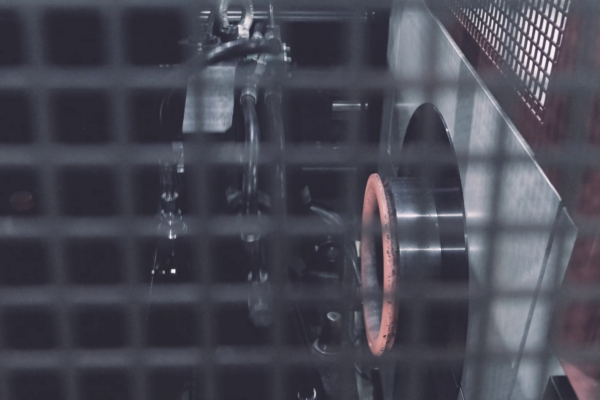

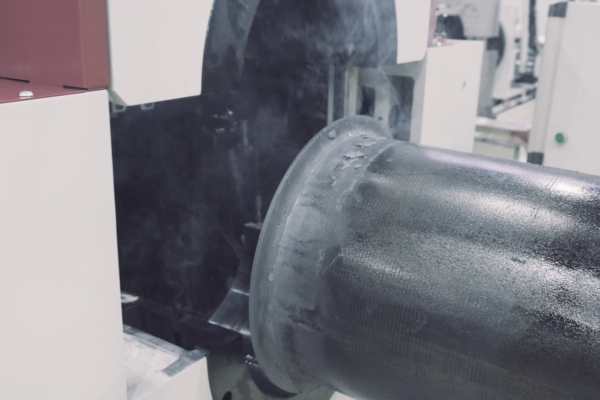

F-400 FLANGING MACHINE FOR BOTH HOT AND COLD FORMING

With the T-DRILL F-400 Flanging machine lips and flanges are formed directly on the end of the pipe – a system that saves up to 40 % in time and costs compared with traditional weld neck flange connections.

The flanging machine F-400 meets the most stringent requirements of pipe manufacturers working with large OD ranges. The machine is capable of both hot and cold forming. The F-400 is also suitable for producing flange pieces.

T-DRILL Flanging method is approved e.g. by:

- Det Norske Veritas

- Germanischer Lloyd

- Lloyd’s Register of Shipping (Carbon Steel etc.)

- Lloyd’s Register of Shipping (CuNi)

- Bureau Veritas

- ASTM

- Pressure Equipment Directive (PED)

TECHNICAL DETAILS

| Mains supply | 200-240 V / 50 Hz /60 Hz, 3-phase 400-480 V / 50 Hz /60 Hz, 3-phase Hz, 3-phase |

| Fuse | Min 3 x 80, Max 3 x 125 A (200-240 V) Min 3 x 40, Max 3 x 100 A (400-480 V) |

| Power supply | 15,5 kW |

| Air pressure | 6 bar (600 kPa) * | 87 psi * |

| Air consumption | 20 l/min *) |

| Oxygen | 2–5 bar (200–500 kPa *) | 29–72 psi * |

| Propane | Max. 2 bar (200 kPa) * |

| Hydraulic pressure | Max. 160 bar | 2330 psi |

| Flanging range | (33,7mm**) 42,4–419 mm | (1.315” ) 1.660” – 16.00” OD |

| Chamfering | 42,4–419 mm |1.660”–16.00” OD |

| Expansion | 100–323,9 mm | 4.500”–12.00” OD |

| Machine dimensions | 2 245 x 1 625 x 1 720 mm | 88'' x 64 '' x 68'' (L x W x H) |

| Package dimensions | Wooden case 3 360 x 1 190 x 2 150 mm | 132'' x 47'' x 85'' Wooden pallet 3 500 x 1 900 x 2 100 mm | 138'' x 75'' x 83'' (L x W x H) |

| Net weight | 4,500 kg | 9,920 lbs |

| Gross weight | 4,800 kg | 10,582 lbs (in wooden case) |

*) Required only with hot forming system

**) Flanging pipes 33.7mm is possible by using forming pin: 5401793

Note! The above values are intended as a guidance only.