HFT-2000 SS

Collaring range: Ø17–54 mm | ¾” – 2″ O.D.

Run tube sizes: Ø33,7–114,3 mm | 1 ¼” – 4″ O.D.

Pipe material: Copper, Stainless steel, Steel

Machine type: Portable tools

Process: Collaring

HFT-2000 SS MANIFOLD FABRICATING MACHINE FOR STAINLESS STEEL

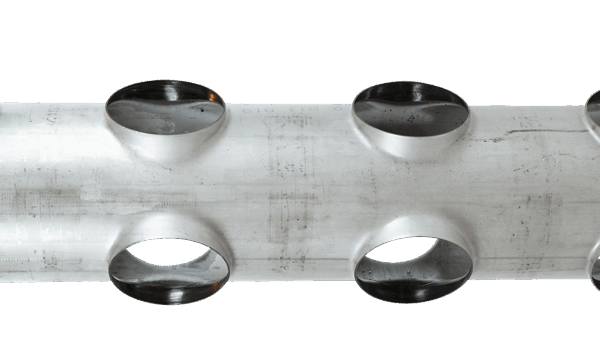

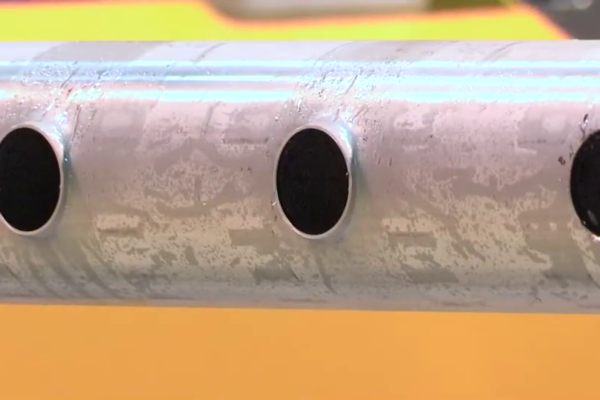

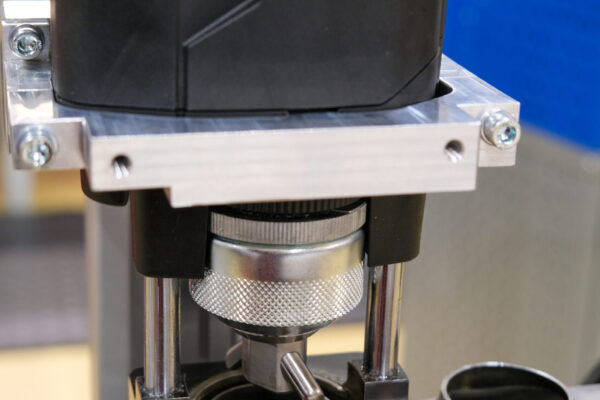

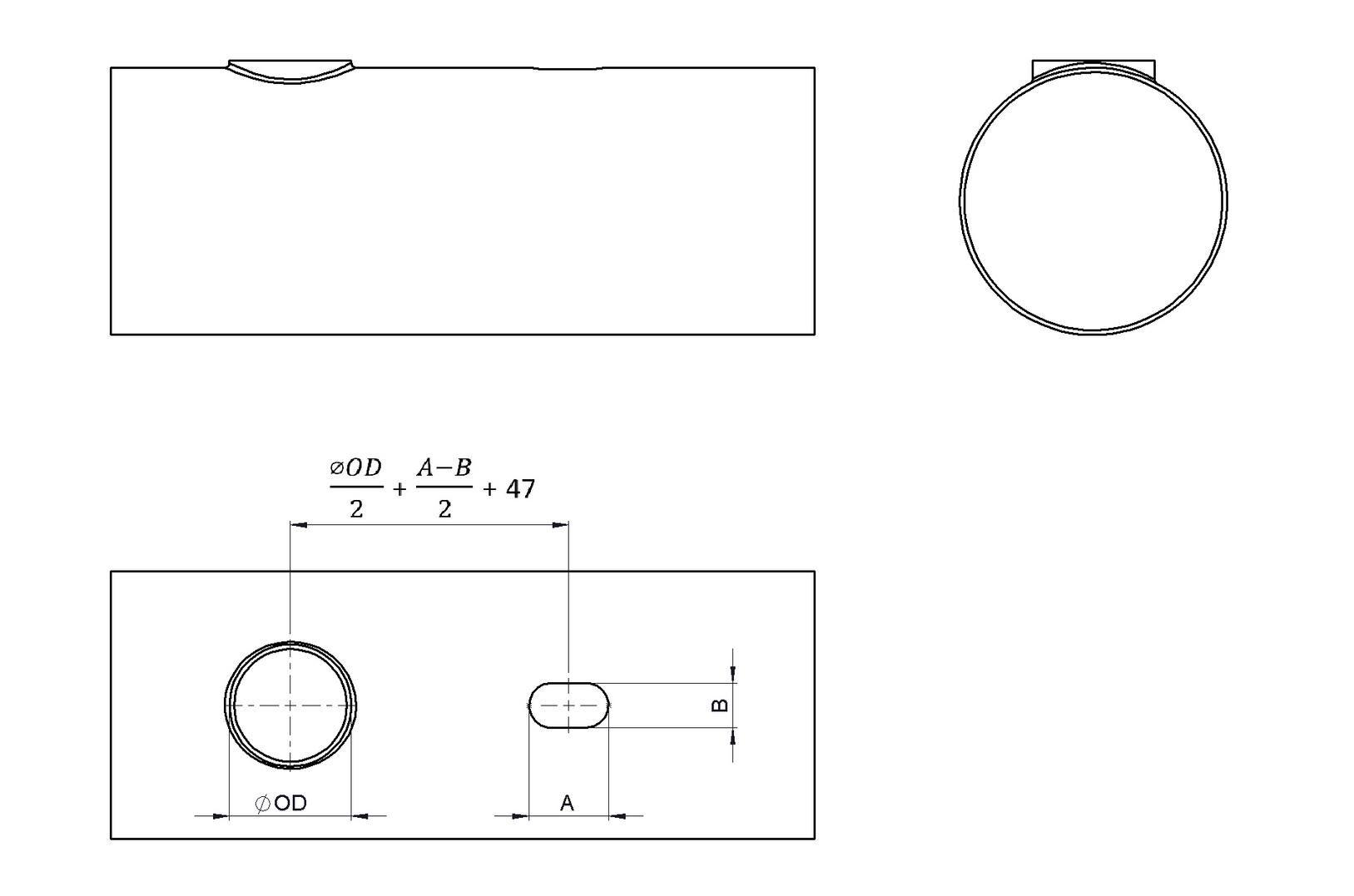

T-DRILL HFT-2000 SS is used in conjunction with the T-DRILL T-54c SST collaring machine for small volume Stainless Steel manifold production. The Hand Feed Table (HFT) is capable of producing collars O.D. 17–54 mm (¾” – 2″) in run tubes O.D. 32–114 mm (1 ¼” – 4″).

T-DRILL collars give the most reliable tube joints being used with the most extreme applications. The collaring unit is effortlessly moved by the operator after each collar is produced. Based on easy “pin-to-hole positioning” it is very productive on standard manifold production. To make the process even easier, there is also an optional digital measuring display available.

Produce five 54 mm (2″) collars in less than ten minutes without moving the tube!

TECHNICAL DETAILS

Note! The above values are intended as a guidance only.