Additional Information

Collaring range:

Lap joint (Drilling/collaring):

ID. Ø6–54 mm | I.D. ¼”–2 1⁄8”

Butt weld joint (Elliptical pilot hole milling/collaring/trimming):

O.D. Ø17.2–60.3 mm | O.D. ¾”–2 ¼”

Butt weld joint (Drilling/collaring/trimming):

O.D. Ø12–58 mm | O.D. ½”–2 ¼”

Run tube sizes: Ø8–114.3 mm | O.D. 5⁄16”–4 ½”

Pipe material: Fe, Steel, Stainless steel, Aluminium, Copper, Copper-Nickel

Machine type: Industrial machines

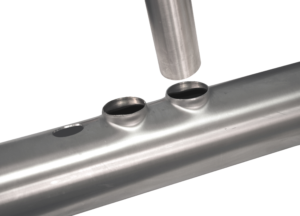

Process: Collaring

T-DRILL S-56 MultiFlex is a highly effective automatic multi-unit collaring machine for producing T-outlets for brazed and welded joints. The machine is designed to meet your specific collaring needs with up to three tool units.

The S-56 MultiFlex produces quality collars up to 60,3 mm (O.D. 2 1/4”). It is ideal for producing variable collar sizes in steel and copper manifolds, but also suitable for all malleable materials (steel, stainless steel, aluminum, copper & copper-nickel). The T-DRILL S-56 MultiFlex collaring process is fully automated and the drilling & trimming processes are optimized. Round pilot holes for lap joint collars are done with the same tool as collaring. Elliptical pilot holes for butt weld joint collars are done with the machine´s optional milling unit, which enables 1:1 butt weld collaring (collar diameter is the same as run tube diameter).

Being an Industry 4.0 ready machine utilizing the latest technology, the S-56 MultFlex is very versatile and easily customized to fit specific customer needs. The machine is easy to program and use, featuring a user-friendly GUI Interface with a color touch panel, adjustable machining parameters, and fine-tuning of motion profiles.

Tailored Solutions:

The S-56 MultiFlex video:

The S-56 MultiFlex collaring machine is perfect for a wide range of materials, including Fe, stainless steel, Al, Cu, and CuNi.

Share on social media