TCC-28 RL & COIL

Pipe diameters: Ø4,76–28,6 mm | 0.187”–1.125”

Pipe material: Aluminum, Copper, Stainless steel, Steel

Machine type: Industrial machines

Process: Cutting

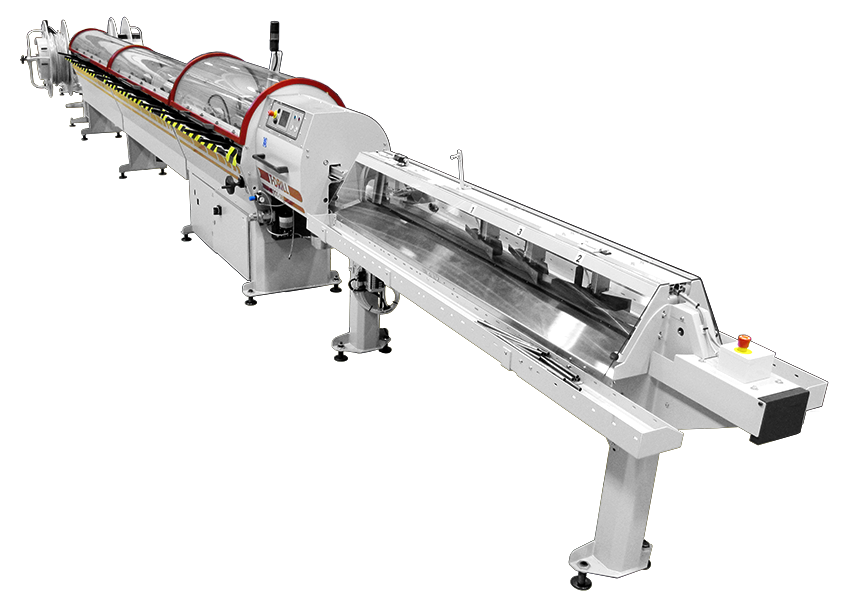

TCC-28 RL & COIL AUTOMATIC TUBE CUTTING CENTER

This machine is the best solution if you need to cut tubes from both coil and rack loading systems for straight-length tubes. It combines both capabilities in a single machine.

Tube diameters 4,76–22 mm (0.187” – 0.866”) of various materials such as aluminum, stainless steel, and brake pipe tubing can be cut using either method, and straight tubes up to 28,6 mm (1.125”).

Typical application areas are, for example, in the automotive and heat exchanger industries, where good cutting quality and superior production speed are needed.

Component Units:

- Pipe Uncoiling Unit: Efficiently uncoils pipes for seamless processing.

- Pipe Straightener Unit: Ensures precise alignment for accurate cuts.

- Rack Loader Unit: Streamlines material handling.

- Cutting Unit: Clean, chip-free cuts without circular saw blades.

- Pipe Sorter Unit: Organizes cut pieces effortlessly.

Advantages:

- Blade Life: No circular saw blades needed, resulting in longer blade life.

- Cost-Effective: Low cutting blade cost.

- Material Efficiency: No material loss between cuts.

- Clean Process: No chips, no need for a chip handling system.

- Washing Not Required: Clean cutting method eliminates the need for washing.

- High Productivity: Fast cycle time, up to ~3000 pieces per hour.

- Quiet Operation: Low operating noise level.

- End-Forming Option: Optional inline end-forming (38 hits) for added versatility.

- Waste Minimization: Systems available for waste material reduction.

- Global Reach: Over 500 TCC machine deliveries by T-DRILL worldwide.

TECHNICAL DETAILS

| Straigth lengths | Coiled tubing | |

|---|---|---|

| Materials | Copper, Aluminium, Steel, Stainless Steel, CuNi, Brass | Copper, Aluminium, Steel, Stainless Steel, CuNi, Brass |

| Minimum diameter | 6 mm / 1/4” | 1,5 mm / .060” |

| Maximum diameter | 50,8 mm / 2” | 22 mm / 1.125” |

| Minimum cut length | For very short cut lengths (less than 50 mm) Cut & Break system, which works for pipes up to ~Ø 20 mm 50 mm with Through cut 75 mm with Pull apart cut | For very short cut lengths (less than 50 mm) Cut & Break system, which works for pipes up to ~Ø 20 mm 50 mm with Through cut 75 mm with Pull apart cut |

| Cut length tolerance | ± 0,1 mm | ± 0,1 mm |

| Maximum wall thickness | 2,5 mm / 0.1” | 2,5 mm / 0.1” |

Note! The above values are intended as a guidance only.