4.7.2024

T-DRILL Oy and Larikka Oy have agreed on a business transaction that covers the intellectual property rights and product rights for five different pipe processing and handling machines and technology, as well as the patent portfolio. The portfolio includes nine main patents and 43 country-specific patents across 24 countries.

28.5.2024

In April, T-DRILL participated in the Tube 2024 trade fair at wire & Tube in Düsseldorf, Germany. T-DRILL has decades of history participating in the biennial trade fair, often described as one of the most significant events in the industry. In terms of the connections made at the fair, Export Manager Ville Hautanen describes Tube 2024 as one of the company’s most successful participations so far.

27.5.2024

T-DRILL joins ACHEMA 2024 in two different booths with its collaring and flanging machines. We welcome you to join us and see T-DRILL machines in action!

20.3.2024

29.1.2024

Picture a man. He is getting off an airplane somewhere in the world after an 11-hour flight. He grabs his belongings, stretches his limbs and says goodbye to the crew who know him by name. He casually gets off the plane and without batting an eye, hops in a cab, travels to his destination – and gets straight to work. Is he a president? A movie star? No. He is T-DRILL’s Service Engineer Harri Aikio.

18.1.2024

We are proud to unveil the latest addition to our portable tool lineup – the T-DRILL T-54c Cordless Portable Collaring Machine.

18.1.2024

T-DRILL's new S-56 PC 1500 Punching and Collaring machine revolutionizes HVACR manufacturing, seamlessly merging collaring and punching unit into one.

30.11.2023

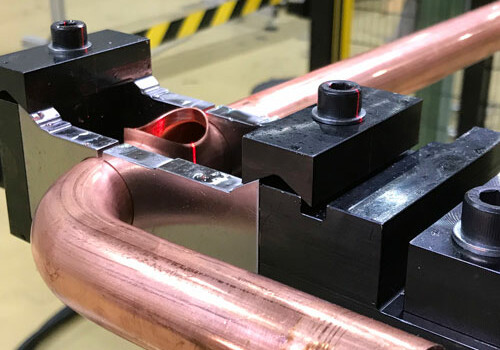

T-DRILL introduces its latest collaring machine for bent tubes.

5.10.2023

On Jan 1st 2023, Toby Allen was appointed CEO of T-DRILL Industries Inc. located in Atlanta, Georgia. The Georgia native, who has been with T-DRILL for almost 25 years, has embraced his new role with gratitude, assuredness and humbleness. Toby’s personal goal as CEO is to keep the business growing and moving forward at a steady pace.

28.2.2023

Juan Ramón from Jartool represents T-DRILL products in Mexico. Ramón has more than 12 years of experience of working with T-DRILL products. There are two main reasons for Ramón’s devotion to T-DRILL: the people and the product.

2.2.2023

T-DRILL systems have been used for producing tubular components for the HVACR field for decades. HVACR is currently going through a shift. As global warming increases, the use of synthetic refrigerants such as hydrofluorocarbons is increasingly restricted. One of the alternatives for HFCs is carbon dioxide, which a natural refrigerant with low environmental impact. The challenge of using CO2 is its high operating pressure. High amounts of pressure in the tubes puts even more emphasis on the durability of the system’s joints. Since The T-DRILL method results in a more reliable, durable joint, it will continue to produce the safest tube assemblies for the HVACR industry as the use of CO2 increases.

8.12.2022

One of the classes taught in the Union Instructor Training Program is called Alternative Joining Methods. Among the methods taught in the class is the T-DRILL collaring method, introduced to the class by T-DRILL's Applications Engineer Dylan Howell.

6.9.2022

Jaakko Anttila had his first job at T-DRILL when he was just 15 years old. Today, Anttila works at T-DRILL as an Export Manager. In the years in between, Anttila obtained two degrees and worked in different positions at different companies and even operated as an entrepreneur.

12.7.2022

We are inviting you to join us at Achema in August.

17.6.2022

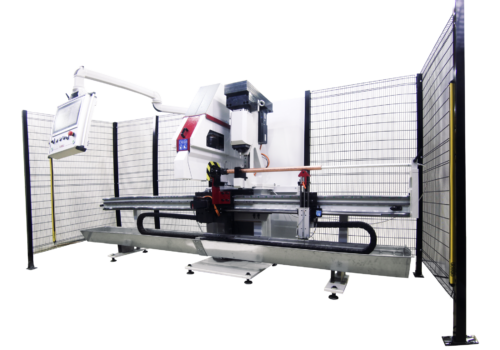

Completely new Tube Branching Center for fastest T-DRILL T-fitting manufacturing ever.

17.6.2022

Globally the first of its kind, T-DRILL’s revolutionary Flanging Machine F-420e, is by far the most advanced flanging machine on the market – implemented with entirely programmable servo technology.

16.6.2022

T-DRILL Industries Inc. has managed to create a solid market in the US for almost 40 years. President Jarno Syrenius believes that the secret to their success lies in their products, local customer service and strategically built partnerships.

4.5.2022

4.5.2022

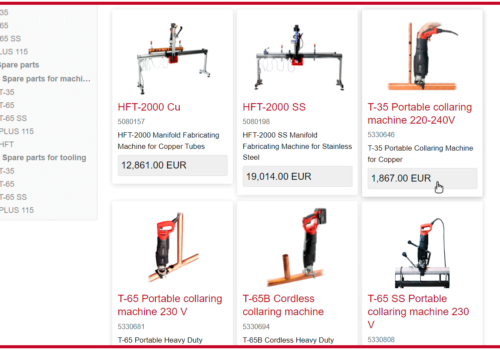

T-DRILL’s Webshop is now open worldwide

Our online store for portable tools is available now for all the countries in the world.

2.5.2022

As of May 1st, Polysoude UK will take on T-DRILL sales in the United Kingdom. The companies’ extending partnership will benefit both organizations as well as customers.

25.4.2022

We are pleased to introduce a new SEC-115 to be part of our selection. An automatic tool changer for five different collaring tools makes the production of manifolds with multiple collar diameters easier, faster, and more productive than ever before.

Partager sur les réseaux sociaux